Products

Case

Farmall 85C – 95C - 105C - 115C

(Stage lllb=T4i)

without preparation of welded front axle support

(Stage lllb=T4i)

without preparation of welded front axle support

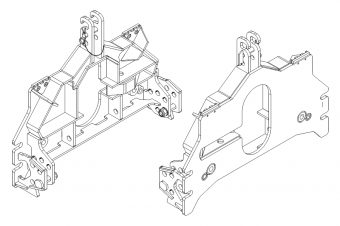

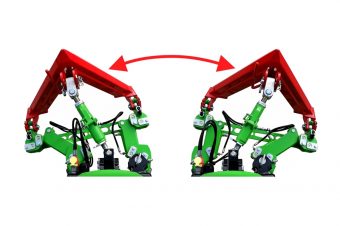

Front Linkage cat. 2

Lifting power 25 kN (2.5 t)

2 double-acting cylinders

Short side rails

Lower links with Walterscheid catch hooks cat. 2

Hydraulic conduits with shut-off valve

up to the hydraulic control valve

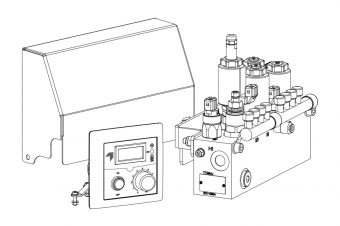

Reversing valve (double-acting/single-acting)

Hydraulic accumulator

Spindle-adjusted top link cat. 2

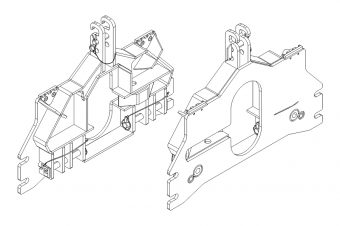

Front PTO

Shaft speed 1000 rpm, gear ratio i = 2.1

Max. continuous power 110 kW / 150 HP

Electrohydraulically actuated

Incl. complete mounting kit

- Front linkage category 2

- Lifting power at catch hook kN (t) 25 (2.5)

- Lifting power at implement center of gravity 17 (1.7)

800 mm from catch hooks kN (t) - Double-acting cylinders •

- Reversing valve •

- Catch hooks Walterscheid cat. • 2

- Top link cat. / thread 2 / M30

- Top link support •

- Front PTO shaft speed/rpm / gear ratio • 1000 / 2.1

- Front PTO shaft speed/rpm / gear ratio ECO o 1000 / 1.63

- Max. PTO power kW (HP) • 147 / (200)

- Max. PTO power kW (HP) ECO o 100 / (136)

- Max. continuous power kW (HP) • 110 / (150)

- Max. continuous power kW (HP) ECO o 88 / (120)

- PTO shaft profile DIN 9611 – 1 3/8″ – 6 •

- Direction of rotation to the right in driving direction •

- When mounting the front PTO, the front axle support has to be cut out. When mounting the front linkage, spacer blocks has to be welded to the side of the front axle support.

• standard version / o on request / – not available

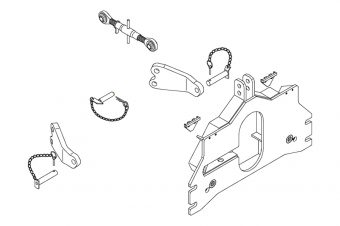

- Municipal mounting plate size 3/5 without further mounting parts for catch hooks width cat. 2

- Municipal mounting plate size 3/5 (VSS-A) without further mounting parts for short lower links / top link

- Mounting kit for municipal mounting plate size 3/5 (VSS-A) with short lower links / top link

- Municipal mounting plate, rigid version size 3/5 (VSS-A) with short lower links / top link

- Push rod for Sauter front linkage

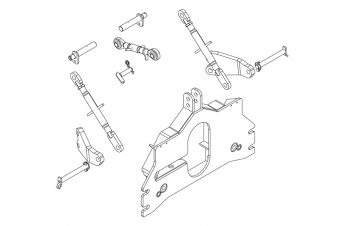

- Hydraulic implement relief, more information see downloads

- Telescopic top link

- Auxiliary headlights

- Tractor triangle, more information see downloads

- Push rod

- Holders for mower relief springs

- Front remote

- Pressure gauge kit

- Reversing valve with reducing throttle

- Hydraulic pipes at the front double-acting

- Light socket 7 poles

- Hydraulic implement relief especially for mechanical control units, more information see downloads

- Ballast support

- Ballast container

- Hydraulic pivot links cat. 2, more information see downloads