Great technology for the work in the field arises from many ideas

Many years of experience, an up-to-date production site and the commitment of the whole staff are the guarantee for optimum quality and enormous flexibility. SAUTER products keep with the latest technological developments. These are only some reasons why SAUTER is known in agriculture.

Our in-house design office is equipped with up-to-date CAD systems and calculation software. Here our innovative ideas are developed and prepared to go into production.

We attach great importance that as many parts as possible are produced in-house; for those a big raw material stock is available.

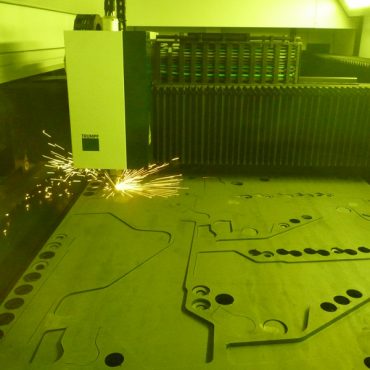

Correct torch cutting and very modern laser oxygen cutting create the condition for exact welding and bending parts.

4 welding robots which produce large quantities of components requiring intense welding work complete the manual welding places.

4 automatic lathes provide high availability, just if it concerns newly developed drive parts.

9 machining centers with individually designed jigs and fixtures and a large tool shop guarantee an exact and efficient production.

The modern powder coating system is the guarantee for a nonpolluting and high-grade varnish.

With our gear production we are able to solve every task regarding motive power engineering in our company.

Owing to a large stock we can guarantee short delivery periods. The parts and implements, perfectly packed and exactly commissioned, are dispatched every day.